ZeroZone ZMZN

Rapid magnetic coupling to work piece

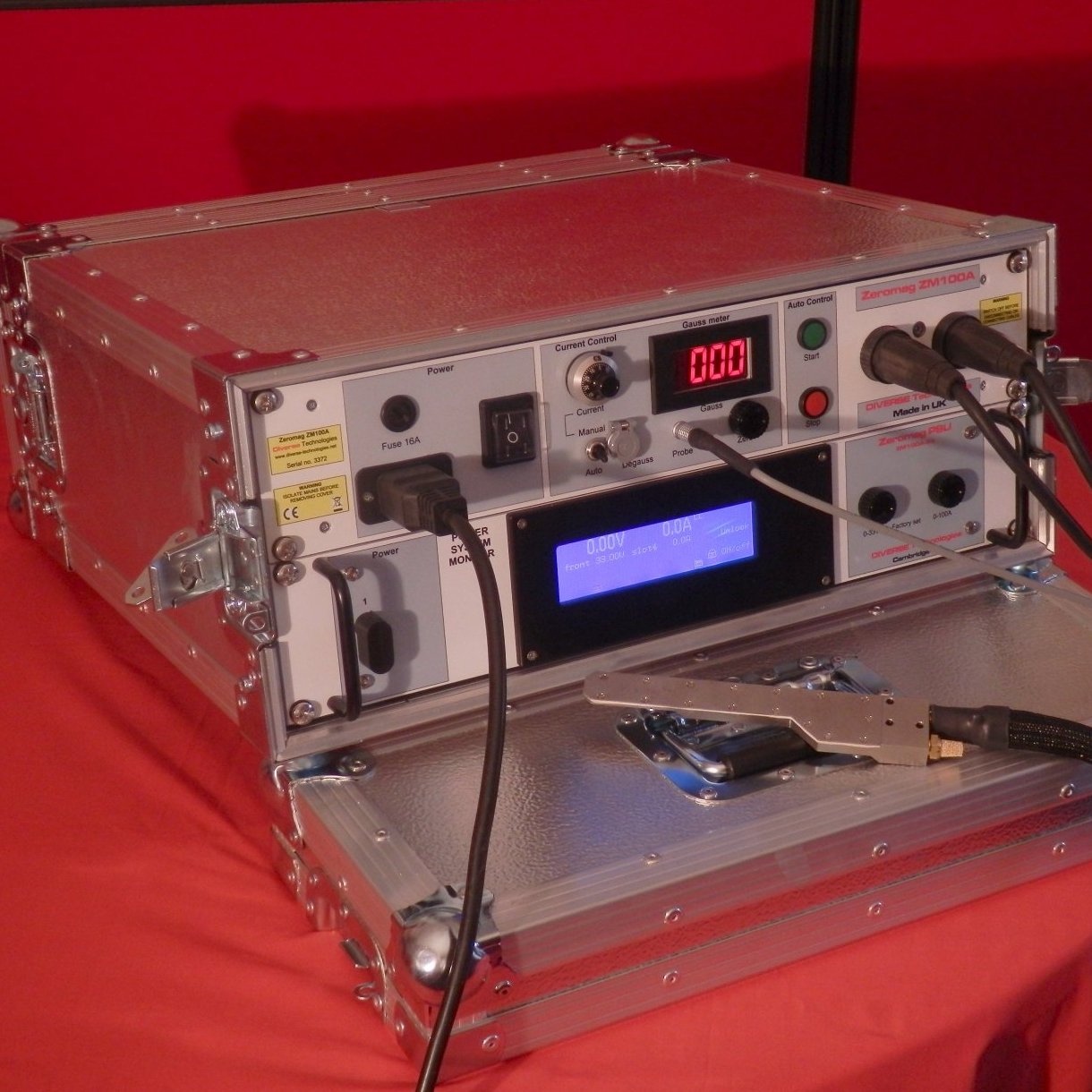

The Diverse Zeromag measures and neutralizes magnetic fields which may be present in the weld preparation region of mating steel components. When working with plate or pipes, the demagnetisation process requires that the magnetic field is controlled via the demagnetizing cables. This works well when the object can be coiled around with the cables but for large diameters or plate applications lay on coils are used. These are cumbersome to deploy and magnetic coupling is not as effective when the coils do not go round the work piece.

For high fields the most efficient way to null the magnetic field is to use ZeroZone. This is prewound with 40 turns and provides a magnetic bridge across the weld prep to allow control of the magnetism.

In operation, ZeroZone is placed across the weld prep. The arms and pole pieces are adjusted so that the active area of the pole pieces are in close contact with both sides of the work piece. ZeroZone is then connected back to Zeromag and the system used as normal. ZeroZone is particularly effective with Zeromag operated in automatic or manual nulling modes

Once the magnetism is nulled, welding can commence. The nulling effect of ZeroZone extends along the weld preparation outside the region of the ZeroZone jaws. In automatic mode ZeroZone can be clamped in position and the welding can progress over an extended range without the need to move ZeroZone.

For large pipes, a Zeromag and ZeroZone each side of the pipe allows two welders to weld unimpeded regardless of the type and level of magnetism in the pipes.