Split bobbins ZMSB

Rapid deployment and removal of demag cable for field nulling

Zeromag ZM100A is used world wide by leading welding companies to overcome arc blow. When working with pipes this process requires demag cable to be wound, typically 20 to 25 turns. Winding can be a slow process typically occurring after fit-up. Split bobbins offer the opportunity to wind the cable off line; bobbins and cable are then passed over the pipe end prior fit-up. Often these are used one either side of the weld preparation. Eye-bolts on the bobbin facilitate hoisting of the cable and bobbin assembly.

Once welding is complete cable can be quickly pulled off the bobbin. Thumb nuts are then loosened and the bobbin can be split for removal from the pipe. The process is then repeated for further joints.

Split bobbins are aluminium construction and manufactured to pipe size, specified at time of order.

Related Products

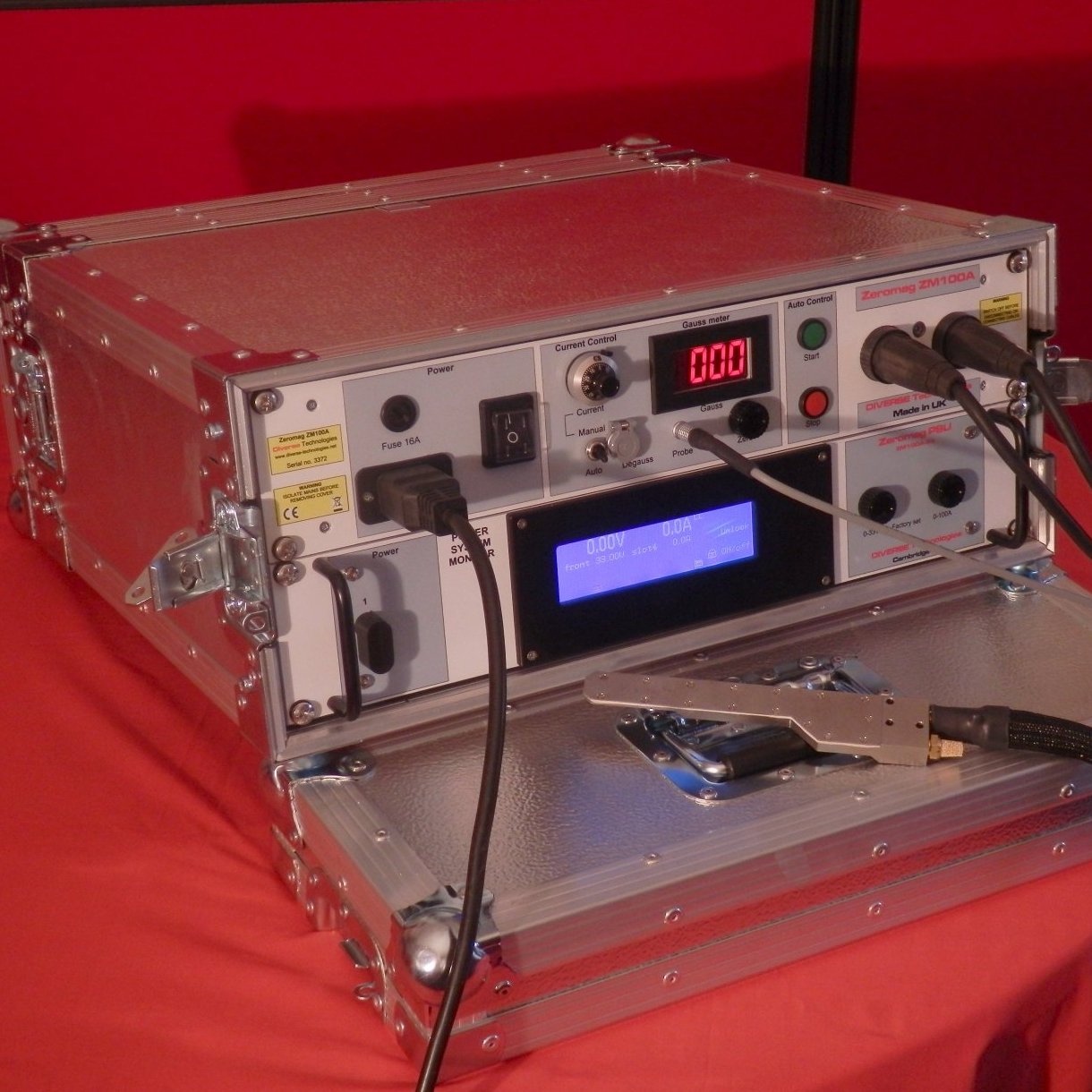

Zeromag ZM100A

Degauss controller

High power Zeromag

ZM50