ZM150x2 Dual degauss controller for Zeromags

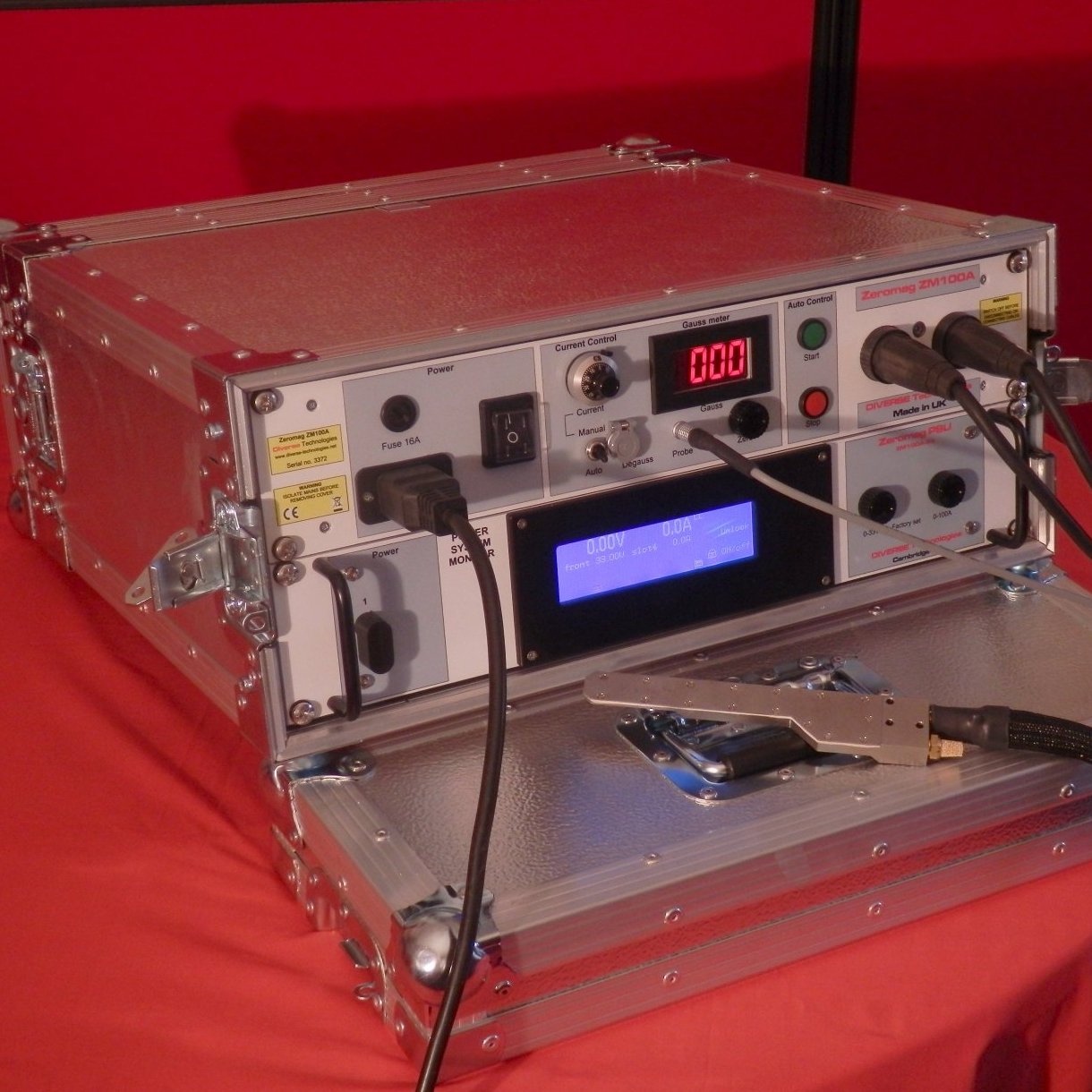

Zeromag controlled by ZM150 degausser is used to degauss pipe joints at fit-up, or pipe ends prior to fit up. For degaussing to be successful a field must be established that magnetically saturates the steel. The maximum field achieved for a particular demagnetizing current depends on the pipe diameter (as this determines the number of turns), the wall thickness and the type of steel. For a standard Zeromag ZM100A joint degaussing is usually possible for pipe diameters to about 16 inches (0.406m).

To increase the degaussing power the dual degausser ZM150x2 provides all of the features of the standard ZM150 but controls two Zeromags. So the degaussing power is 3kW with two standard ZM100A, 4.5kW with a ZM100A-33 and ZM100A or 6kW with two ZM100A-33. These higher powers allow joint degaussing on larger pipes and thicker walls. The table below shows a rough guide to the pipe OD for a particular Zeromag power and wall thickness for achieving 1.5 Tesla in the steel. This is for a standard carbon steel but do note that the degaussing efficacy will depend on the details of the job, in particular the pipe steel, OD, wall thickness and cladding.

|

Zeromag power (kW) |

Pipe OD for 1.5T induced Wall thickness 1cm |

Pipe OD for 1.5T induced Wall thickness 2cm |

|

1.5kW (1 x ZM100A) |

16″ / 0.406m |

10″ / 0.254 |

|

3kW (1 x ZM100A-33 or 2 x ZM100A) |

28″ / 0.711m |

16″ / 0.406m |

|

4.5kW (1 x ZM100A-33 and 1 x ZM100A) |

38″ / 0.965m |

22″ / 0.559m |

|

6kW (2 x ZM100A-33) |

48″ / 1.219m |

27″ / 0.686m |

Clam coils are recommended for rapid deployment of sufficient demag turns, the number of clams required will depend on the pipe size and degaussing power available, contact Diverse for advice. Clam coils can be connected in series and are available as single wrap (25 turns per clam) or double wrap (50 turns per clam).