Bobbins ZMBOB

Rapid deployment of 100m of demag cable for pipe-end degauss

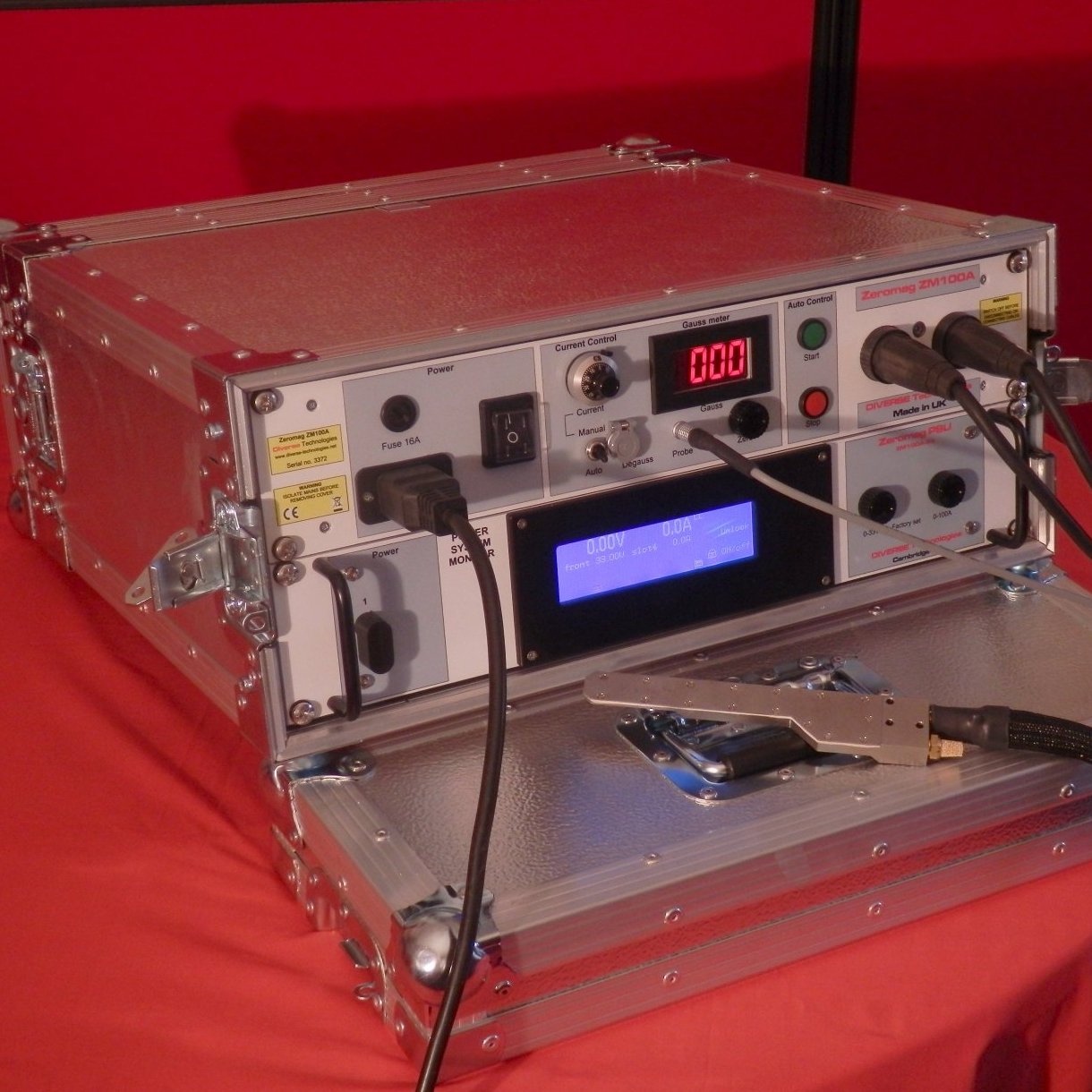

Zeromag ZM100A is used world wide by leading welding companies to overcome arc blow. The ZM150 degausser in conjunction with the Zeromag ZM100A is used to demagnetize pipe-ends prior to fit-up, or joints post fit up.

Successful degaussing of pipe-ends requires the application of fields large enough to magnetically saturate the steel. The magnetic field required depends on the type of steel, the number of turns, the current and the ratio of pipe diameter to coil length along the pipe. Thus there are a variety of conditions that determine whether the saturation magnetic field is reached. Generally for most steels a pipe diameter of less than 28” (0.7m) will be saturated using Zeromag.

Turns can be applied to the pipe end by manually winding the 50 m demag and 50m demag extension cables supplied in the standard package (DKPW). This is time consuming and not always convenient. The Zeromag bobbin applies 100m of cable turns repeatedly and rapidly to the pipe-end.

Connection cables are supplied to connect the bobbin to Zeromag. Bobbins can be supplied for any user defined pipe size.

For degaussing larger pipe ends two bobbins, connected in series, can be used with the high power Zeromag ZM100A-33.

Related Products

Zeromag ZM100A

Degauss controller

High power Zeromag

ZM50